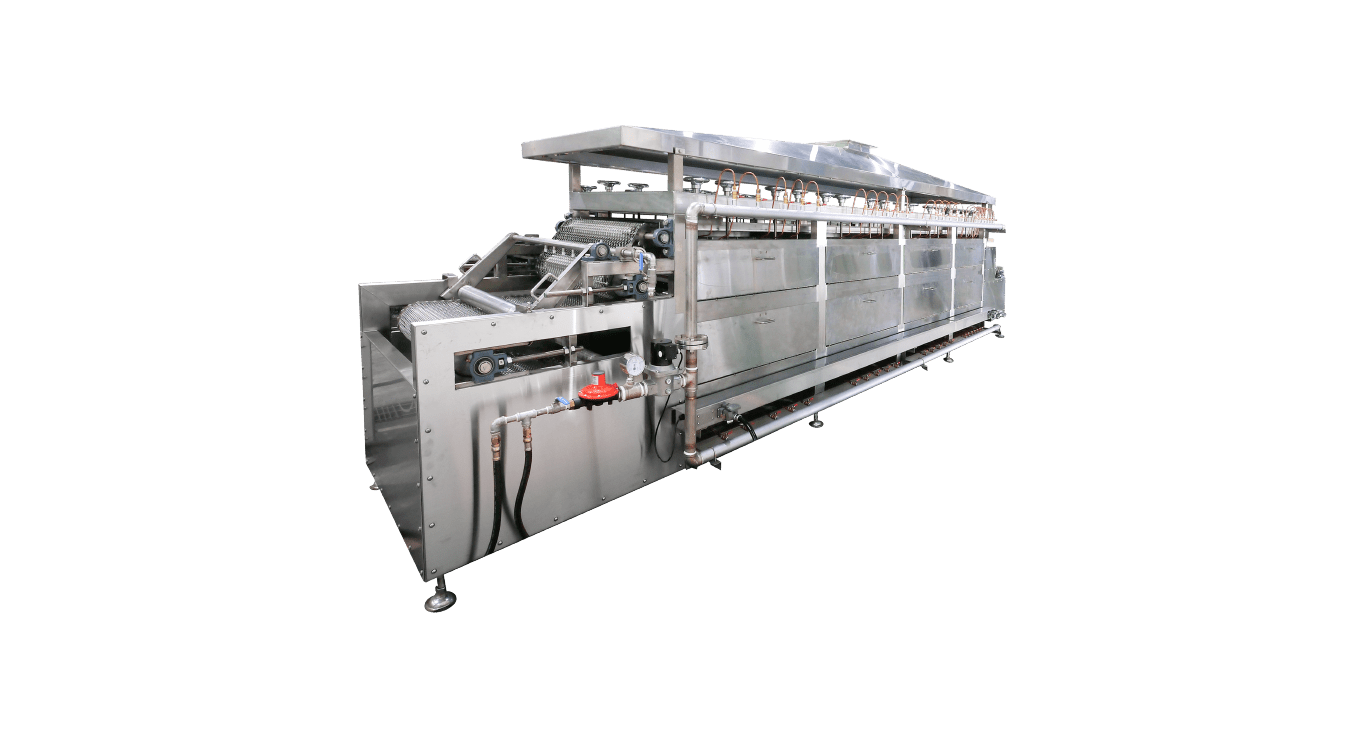

Infrared drying mainly uses infrared radiation to directly penetrate the surface of the materials, causing the molecules inside the materials to vibrate and generate heat energy to achieve the drying effect. It is different from traditional heat conduction drying; the traditional thermal drying relies on the thermal conduction, thermal convection and radiation to transfer heat energy from the outside to the inside of the materials.

The core components of infrared drying equipment include: 1. Infrared emission source, 2. Reflector, 3. Fan, 4. Control system. The infrared emission source usually uses specially designed lamp tubes or advanced heating elements.

During the operation of dryer, infrared rays have excellent permeability and can directly penetrate the surface of the materials, quickly increase the internal temperature of the materials and accelerate the evaporation of water. The reflective cover specially designed to improve efficiency can effectively reflect and concentrate infrared energy onto the target materials and further enhance the drying effect.

Food | Printing | Paint | Wood processing | Ceramic manufacturing | Pharmaceutical manufacturing | Medical materials manufacturing

HOW TO GET A SOLUTION?

LET OUR TEAM KNOW YOUR NEEDS VIA "ADD TO INQUIRY LIST" ABOVE, MAIL OR PHONE. TSHS'S PROFESSIONAL CONSULTANTS WILL HAVE DISCUSSION WITH YOU AFTER ASSESSING YOUR PRODUCT AND PLANNING. ACCORDING TO YOUR SITUATION, OUR TEAM WILL PROVIDE THE SUITABLE ADVISE TO YOU. IF YOU HAVE ANY QUESTIONS ABOUT DRYER MACHINE, PLEASE FEEL FREE TO CONTACT US FOR FURTHER DISCUSSION.