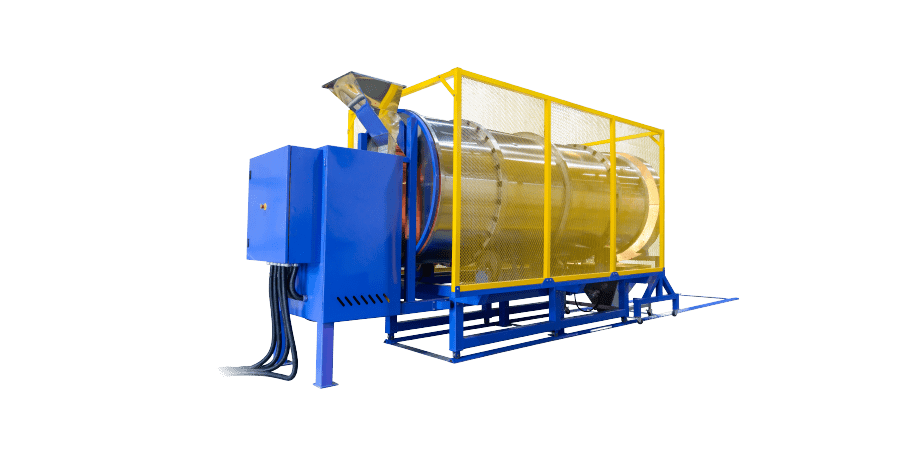

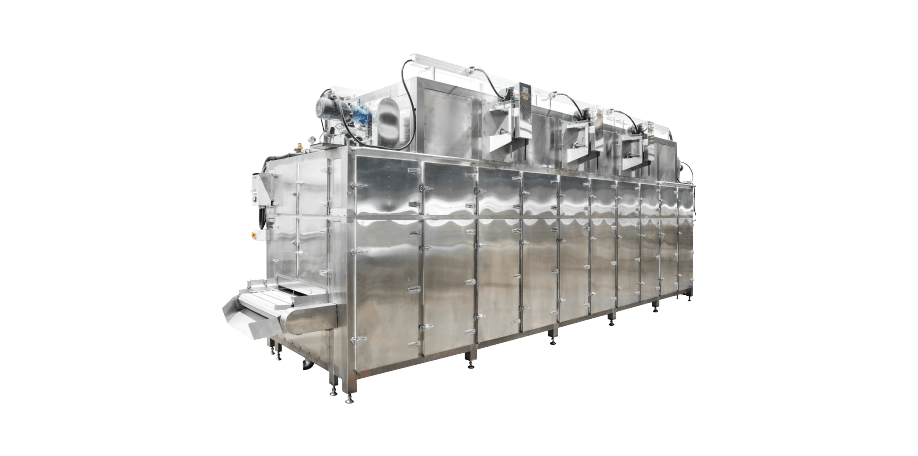

TSHS owns many years of experience in manufacturing drying equipment; we have the ability to provide drying equipment for dewatering rubber materials. In order to ensure that customers can achieve the best drying results in the shortest time, we provide customized and efficient design services on rubber material drying equipment. The dryer adopts a user-friendly control panel; the equipment parameter adjustment process is simple and easy to understand. Even novices can quickly become familiar with equipment operation.

There are many types of rubber materials, including natural rubber (NR), synthetic natural rubber (IR), nitrile rubber (NBR), styrene rubber (SBR), silicone rubber (VMQ), fluorine rubber (FKM) and ethylene propylene rubber (EPM), etc. In order to meet the professional dewatering and drying requirements of rubber materials, the TSHS design team has carefully invested in the R&D of high-efficiency rubber drying equipment.

Rubber has unique properties, such as high temperature resistance, oil resistance, chemical resistance, anti-aging and cold resistance, etc. It is widely used in many fields. From rubber for automobile and motorcycle machinery, customized rubber products, circular ring gaskets, to rubber silicone parts in the electronic field, conductive rubber silicone products, sports and medical rubber products, and rubber mold development, all of them show the wide range of rubber materials application.

We are eager to work with the industry to develop and explore more possibilities for rubber dryer equipment. If you have any needs about rubber material drying equipment or want to know more about our rubber drying technology, please feel free to contact us via email at [email protected].

Temperature control: Avoid excessive temperature causing rubber aging or damage.

Time management: Proper drying time can ensure the quality of rubber.

Material Inspection: Regularly check the rubber during drying to ensure it is not damaged.