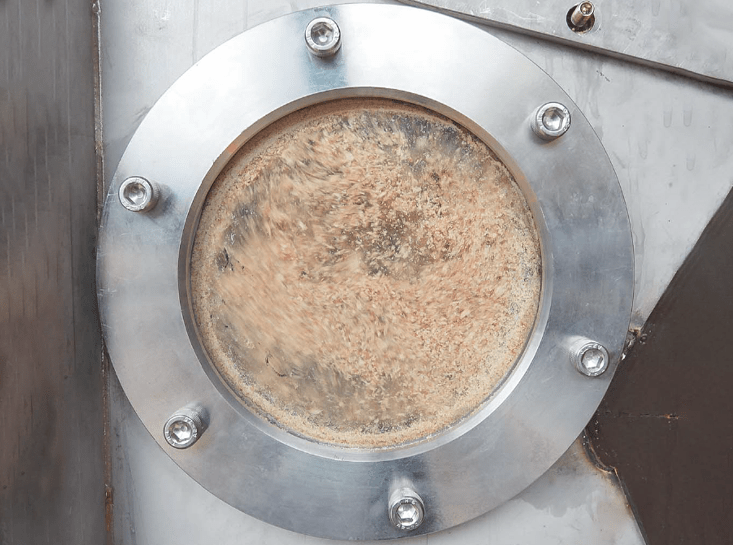

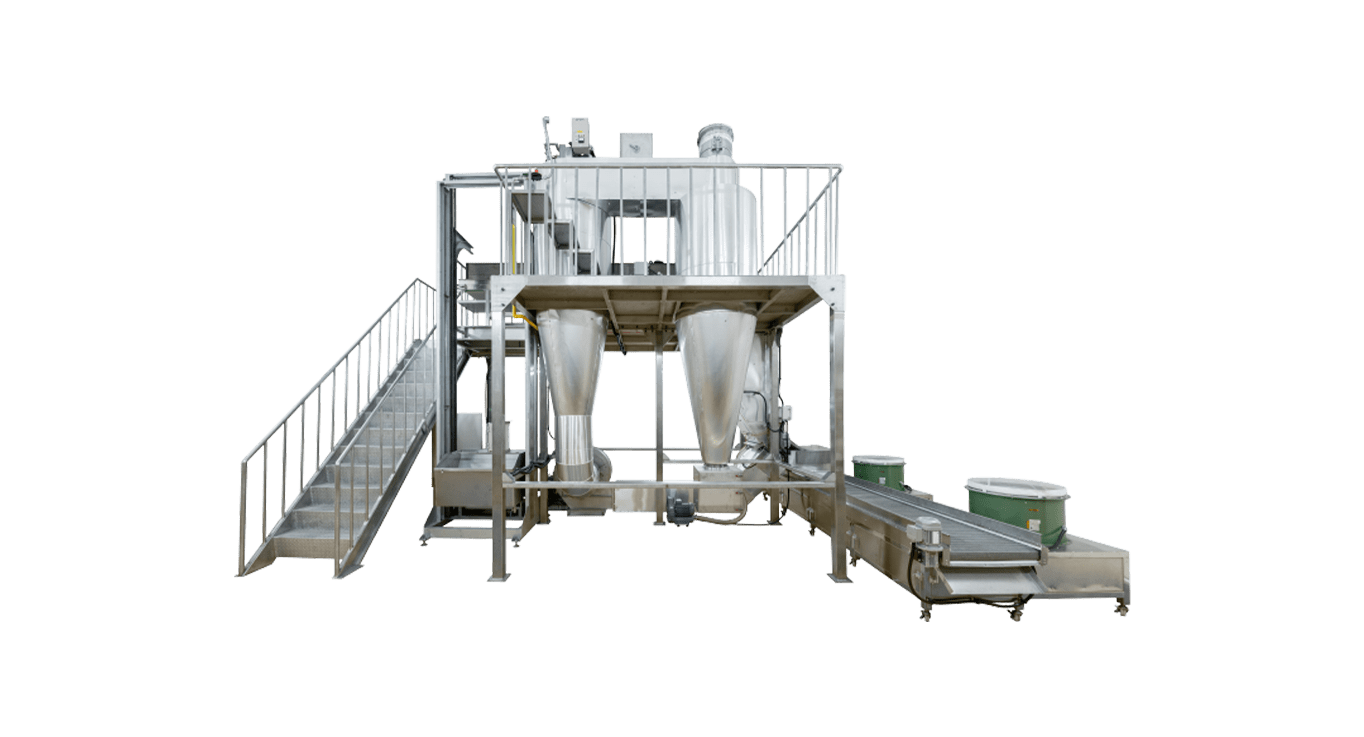

The cyclonic type roasting is a roasting or drying process based on high-temperature hot-air and its flow characteristics. During the roasting process, the material turns in a swirling direction. this drying method is mainly used in food processing production lines, suitable for granular products that are not easy to stick, such as coffee beans, nuts, seeds, and bean dregs, etc.

The cyclonic type hot-air roasting system ensures that heat energy is evenly transferred to the drying chamber through high-efficiency hot-air circulation design. Equipped with professional heating elements and powerful windmills, the materials to be dried can be quickly turned and evenly heated, achieving ideal high-quality products and meeting market demanding.

During the roasting or drying process, the central control panel is equipped with an intelligent monitoring system to accurately control the temperature, save processing time and improve production efficiency. Meanwhile, it is designed with a recycling system to effectively recycle and reuse heat energy to achieve high efficiency and energy saving.

It can effectively and quickly cool down the products and facilitate the connection of subsequent processes, allowing for consistent operation and continuous production.

An intelligent production management monitoring system exclusively developed by TSHS can set processing parameters according to product characteristics. The intelligent production management system has functions such as data recording, maintenance emergency notification, and real-time production line management.

HOW TO GET A SOLUTION?

LET OUR TEAM KNOW YOUR NEEDS VIA "ADD TO INQUIRY LIST" ABOVE, MAIL OR PHONE. TSHS'S PROFESSIONAL CONSULTANTS WILL HAVE DISCUSSION WITH YOU AFTER ASSESSING YOUR PRODUCT AND PLANNING. ACCORDING TO YOUR SITUATION, OUR TEAM WILL PROVIDE THE SUITABLE ADVISE TO YOU. IF YOU HAVE ANY QUESTIONS ABOUT DRYER MACHINE, PLEASE FEEL FREE TO CONTACT US FOR FURTHER DISCUSSION.